Simpro Handling Equipment

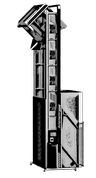

MegaDumper SS

Heavy-duty food grade stainless steel bin lifter.

The MegaDumper SS is Simpro’s largest bin lifter for hygiene-critical applications. With polished 304-grade stainless steel construction, electro-hydraulic operation and a unique tipping geometry, it is the ultimate solution for elevating bulk materials in a food production environment.

Able to convey more than 20 tonnes of material an hour to heights beyond ten metres, the MegaDumper SS requires less than two square metres of floor space – and unlike competing solutions such as belt conveyors and bucket elevators, it has a simple design with no inaccessible spaces or enclosed mechanisms.

This means it can be completely cleaned and sterilised in less than ten minutes.

The MegaDumper SS was originally designed for emptying Nally® MegaBins® (a bulk bin widely used in the food processing industry), but a range of cradles are now available to suit almost any large bin, box, drum or mixing bowl. Floor space requirements do not change regardless of tipping height – even when lifting bins weighing up to 600kg – since the weight of the bin remains within the footprint at all times.

Like all Simpro products, the MegaDumper SS was designed from the ground up for safety. The standard model has full-height guarding and a safety interlock system to comply with ISO12100 (AS/NZS4024) to Cat1/PLc, but the specifications can be upgraded to Cat3/PLd or Cat4/PLe if required. A compressed-air power system is available for use in volatile or explosive environments.

Since its introduction in 2002 the MegaDumper SS has proven to be remarkably reliable in even the most demanding of applications, and has been chosen by dozens of leading food-processing companies including Nestle, General Mills, Fonterra, Goodman Fielder, Cadbury, Tasti Products and Bundaberg Brewed Drinks.

Options and Accessories

The MegaDumper SS is a development of Simpro's tried and tested Dumpmaster product, and supports the same huge range of options for custom requirements. A selection is listed below, or you can view the Dumpmaster options page here.

- Standard weight capacity of 600kg, higher capacities an be engineered on request

- Custom tipping heights from 700mm to beyond 10 metres

- Power supply: 1-phase mains, 3-phase mains, battery, or compressed air

- Cradles available to suit all common industrial containers including MGBs, Nally Megabins, Dolav bins, drums, mixing bowls and many more. Custom cradles can be designed for unique applications

- Uprated safety standards compliance to Cat3/PLd or Cat4/PLe

- Tipping chutes for use when the machine cannot be placed immediately beside the destination receptacle

- Autocycle controller with adjustable timing.

- Programmable Logic Controller (PLC) for custom operational logic or integration with automated production lines

- Custom control locations, such as door-mounted, pendant-mounted, or remote

- Emergency Stop button(s)

- Mounted on castor wheels or bolt-down lugs

Features

Our local and international partners…