Workstation Cranes & Devices

Workstation Bridge Cranes

Gorbel® – The World’s best Enclosed Track Workstation Cranes and Monorails

Gorbel® Workstation Ceiling Mounted Bridge Cranes and Freestanding Bridge Cranes are a proven way to improve productivity, increase quality, and provide a safer work environment. Both the runway and bridge component of Gorbel Workstation Bridge Crane Systems utilize enclosed track that is high in strength and low in weight.

Spanning up to 10m and lift capacities between 125 and 2000 kgs, our ergonomic crane products guarantee increased productivity. Regardless of your Materials Handling needs, Gorbel workstation cranes are sure to handle any project. Call us, we can design a solution to best fit your application.

- Enclosed track with easy movement and direct/accurate load movement

- Reduced support structures so work areas are kept clear of obstruction

- Multiple track profiles (125kg to 2000kg) and spanning capabilities, allowing flexible crane configuration

- 3 to 1 superior ease of movement compared to I-Beam cranes

- Reduced risk of job-related injury as well as significant increases in work productivity

Features

- Workstation cranes create safe work cells by providing flexible lifting and shifting capacity over a wide area

- Avoid crippling injuries, with a safer lifting solution.

- Unique design provides 100:1 ergonomic ratio. Move 1000kg with 10kgs of force.

- Productivity gains of up to 28%.

- Available as ceiling or floor mounted bridge cranes, jibs and monorails.

- Runway Spans up to 9.1 metres.

- Bridge Lengths up to 10.3 metres.

- Modular, durable and tough.

- Easy to install and relocate.

Applications

- Workshops, production lines

- Stacking, moving and emptying bags

- Steel and timber movement

- Roll and drum handling

- Die changing

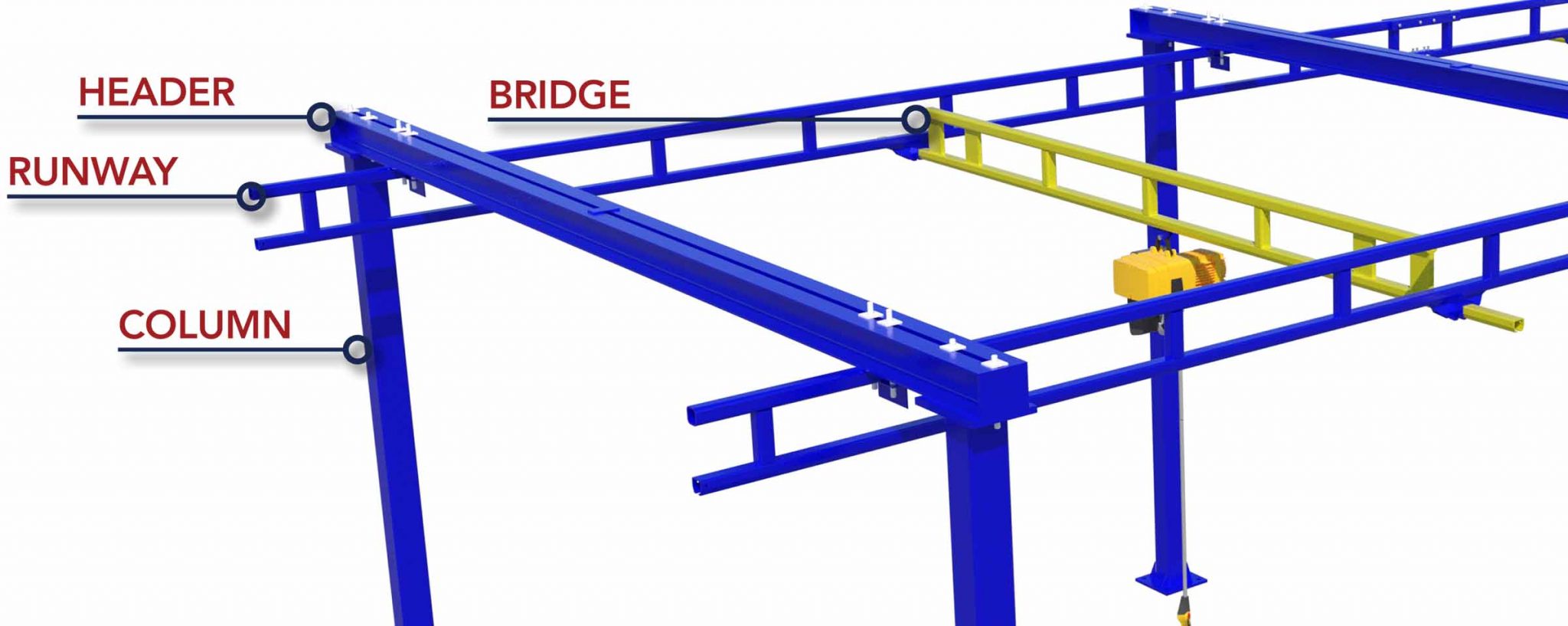

The Anatomy of a Workstation Crane

Bridge cranes cover rectangular work areas, while monorail systems can be used to move loads along a linear path, cover various work area shapes, or to link work areas together.

Bridge

The bridge is the only part of the work station crane in motion. It supports the lifting device, and facilitates the movement of your load along the X and Y axis. Bridges can be as long as 10m, and are available in steel or aluminium.

Runways

The bridge's end trucks ride within the track of the crane's runways, which determine the overall coverage area of your work station crane. The track used for runways can be spliced together, to span any distance.

Column (free standing only)

The columns are the "legs" of a freestanding work station crane, and are bolted to the floor while supporting the columns and runways. The distance between columns is determined by your crane's overall capacity and the selected track type.

Header (free standing only)

The work station crane system’s header is made of back-to-back “C” channel, which allows for easy connections to the runway hanger support hardware.

What do they do?

Gorbel Workstation Cranes provide a load handling and positioning function from above the work cell. They incorporate an articulating structure above the workstation from which is suspended a hoist or other lifting device. This results in the ability to move the load horizontally and vertically throughout the workstation.

They have a multitude of uses including moving components in and out of processing machinery, moving components, tooling or fixtures on production lines, positioning welding equipment or wire feeders and turning or positioning weldments during fabrication.

Gorbel Workstation Cranes can be configured as follows…

Bridge Crane (Ceiling Mounted)

Incorporates two parallel runways, suspended from the building ceiling, bridge can travel. A hoist trolley or crab can travel along the bridge, thus providing full coverage over a rectangular work area. Multiple bridges can be attached to a single bridge and the capacities of these bridges can vary according to need.

Freestanding Bridge Crane (Floor Mounted)

As above, except that the runways are supported on a freestanding structure.

Monorails

For linear movement. Can be integrated into a total system with extra track, curves, interlocks and switches

Download PDF Brochure

Our local and international partners…

Plain Steel Track

Plain Steel Track Trussed Track Profile

Trussed Track Profile Aluminium Bridges

Aluminium Bridges