Workstation Cranes & Devices

G-Force Intelligent Lifting Devices

Gorbel’s intelligent lifting: speed and responsiveness of the human hand with the strength of a machine

G-FORCE – The best Lifting Device in the World. The G-Force uses patented technology and an industrial processor controlled drive system to deliver unmatched lifting precision and speed.

Manufacturing and material handling companies no longer have to trade off between productivity, profitability, and safety. Gorbel’s G-Force® Intelligent Lifting Device offers an affordable and innovative way to enhance and achieve balance among all three of these attributes.

G-Force technology fills the void between traditional lifting devices and completely automated robotic solutions. These devices use the human’s intelligence and adaptability for guidance, but the work is done by the device.

Gorbel’s G-Force Intelligent Lifting Devices use exclusive patented technology and an industrial processor-controlled servo drive system to deliver unmatched lifting precision and speed. Their fusion of advanced technology and basic human guidance maximize your productivity while minimizing the risk of injury to your operators.

Available in models from 75 kg to 600 kg. When precision, lifting power and speed are necessities, turn to the Gorbel Patented G-Force.

- There are two models of Gorbel Intelligent Lifting Devices to choose from: the Q and the iQ. The Q model is our feature packed base model

- The iQ model offers a wealth of additional intelligence features

- Multiple handle configurations

What is G-Force?

G-Force is a technology that enables effortless, user-friendly heavy load manipulation, increasing manufacturing productivity speed by 70% and precision by 51% when compared to other lifting methods. By reducing wear on the worker and energy expenditure when compared to other lifting methods, the use of G-Force enables ergonomic lifting and a safer work environment for your people.

Why Gorbel G-Force?

Investing in a G-Force has been proven to increase production volume and reduce the cost of damaged goods, increasing your profitability. Choose Gorbel’s 40+ years of experience in ergonomic lifting and material handling and its team of engineers and their expertise, backed by countless testimonials from satisfied dealers and customers, to meet your facility’s needs.

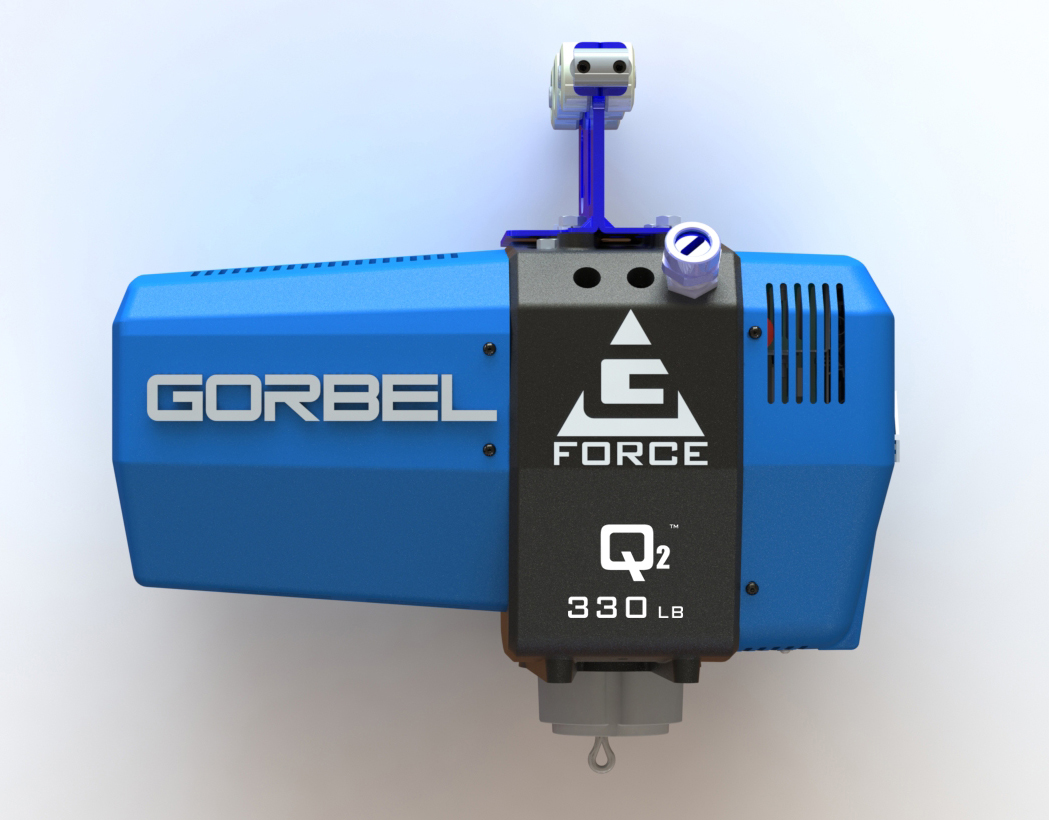

G-FORCE Q

G-FORCE Q

The base model, the G-Force® Q2, is loaded with intelligence features for most applications, offering the same speed and precision as our higher end, iQ2 model.

- 2 user configurable Inputs and 2 Outputs on the handle. This allows for more customization over a wide range of applications.

- Ability to set 3 sets of virtual limits for precise control

- Servo controlled processor system

- Tablet or computer based Smart Connect user interface makes configuration a breeze. Three levels of password protected access so different user types have access to the configurations based on their needs.

- Built in wireless connectivity via Wifi. This provides the ability to service and troubleshoot without the need for Ethernet or USB (though both are still provided as a standard)

G-FORCE iQ

The enhanced model, the G-Force® iQ2, offers even more configuration options with electrical control Input/Output (I/O) points at the handle and in the actuator.

The enhanced model, the G-Force® iQ2, offers even more configuration options with electrical control Input/Output (I/O) points at the handle and in the actuator.

- 8 Configurable inputs and outputs on the handle and 8 dedicated input and 4 output on actuator. This allows for more customization over a wide range of applications.

- Multiple sets of virtual limits for precise control

- Servo controlled processor system for precise control of angular or linear position, velocity, and acceleration

- Tablet or computer based Smart Connect user interface makes configuration a breeze. Three levels of password protected access so different user types have access to configurations based on their needs.

- Built in wireless connectivity via Wifi. This provides the ability to service and troubleshoot without the need for Ethernet or USB (though both are still provided as a standard)

Applications

- Automotive assembly (engines, transmissions, chassis components)

- Heavy equipment manufacturing

- Tool & die changeouts

- Natural gas & oil industry (valves, drilling components, etc)

- Repetitive lifting jobs

- Parts assembly

- Machining

- Process equipment maintenance

- Covering larger single work areas

Download the G-force PDF Brochure

Download the G-force PDF Sell Sheet

Our local and international partners…

G-FORCE Q

G-FORCE Q