Lift Tables

SAFETECH Scissor Lifts

Scissor lift tables by Safetech combine an extensive range of capacities, features and options to provide the factory and warehouse with lifting and work positioning.

SMARTLIFT controls are standard on all tables. Unique to Safetech they provide automatic down-indexing. Electronic diagnostics and enhanced safety features.

- Manual and powered turntables.

- Tilting decks.

- Varied deck sizes and surfaces available.

- Designed for safety, Safetech scissor lift tables meet or exceed all industry standards.

Standard Lift Options

Safetech have designed and manufactured thousands of scissor lifts and offer a wide range of options that can be easily be added to any table.

- Manual or automatic turntables to rotate the load.

- Tilting decks that present the product to the operator.

- High cycle capacity.

- Safety bars or skirts to protect operators.

- Varied deck construction, stainless steel, chequerplate and more.

- Special frames to capture the load.

- Adapted for use as personnel lifts.

- Low height tables for use with hand pallet trucks.

- Controls can be automated or interlocked with associated equipment

Features

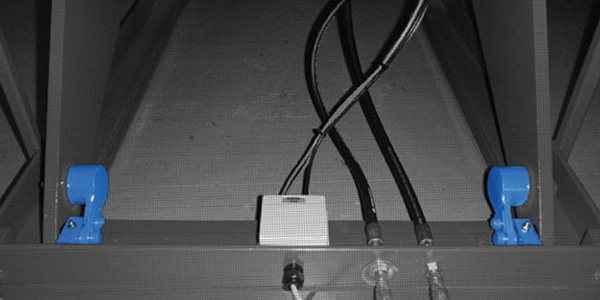

Flow Control Valve

Provides incremental control of descent speed. Eliminates the possibility of the platform plummeting in the unlikely event of a hose failure.

Maintenance Chocks

Locks the lift table in fully raised position for safe access to the underside of the table.

Safety Bar

This highly effective safety device halts the downward motion if an obstruction is detected during descent.

Super High Cycle Modifications

Safetech super high cycle lift tables are designed to work in a high pace, high demand, in-line applications.

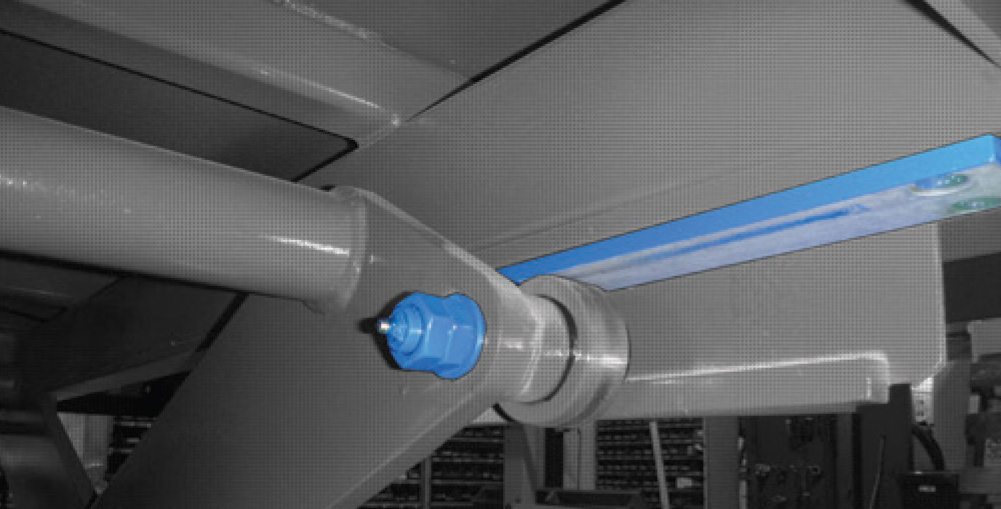

- Custom designed scissor lift with greasable pivots (rollers/hinges, cylinder ends), replaceable roller paths (4) from Bisalloy 80.

- Replaceable leg centre bosses & bolt on hinges for applications that demand longevity, reliability and ease of maintenance.

Cylinder hinge ends Include greasable pivots

*not available on all models

Replaceable Centre boss

Bolt on hinge blocks upper and lower

Greasable Roller followers and Bisalloy 80 roller

Workstation Platforms

Integrated In-line Auto System

Safetech lift tables are used in-line with auto systems. These lift tables are generally working a high pace 24/7 operation.

Some of the features generally required for these applications are; custom high cycle options including constant running power unit with upper and lower limits.

Customers can also choose to control the table with their own PLC applications, include in-line board feed system, dual pallet feed, air cons, food packaging and general warehouse.

User-friendly lift controls

Custom High Cycle Options

End of Line Palletising

Lift tables are used at the ends of conveyor line where goods are being either decanted or palletised. These tables generally have a turntable, manual or powered, to assist the operation with the loading unloading of goods, combine these up/down indexing options so the operator only needs to tap the button.

Applications where pallets are made up of difference weights and heights, benefit from a hydraulic lift table due to the ability to position the platform at any height.

Safety features include safety bar around the perimeter of the table to stop decent if anything was to come in contact. Safety skirt to protect operator from scissor mechanism.

Applications include: Pharmaceutical, cold storage, Retail DC, warehousing, food.

Download General Scissor Lift Brochure

Download Super High Cycle Modififications Brochure

Download Workstation Platforms Brochure

Our local and international partners…